Detection process

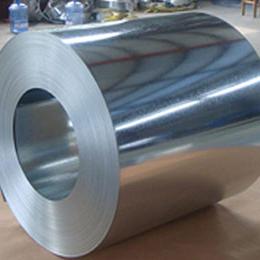

Detection ProcessEach batch of raw materials is put into storage and each roll of finished products needs to go through a strict testing process. And periodically submit for inspection to national authoritative testing institutions as needed. A comprehensive quality control system and strict testing procedures are the only way to ensure product quality.

-

01

Raw material inspection

The raw materials of our products are many sizes cold-rolled steel sheet and coatings. The testing of raw materials mainly includes: surface thickness, width, plate shape, surface quality and so on. Coating testing mainly includes: color difference, bending, pencil hardness, MEK, impact and other performance testing.

-

02

Production Inspection

Production online inspection refers to the real-time monitoring of product appearance quality during the production process, mainly including the appearance observation of finished products such as board shape, board surface, etc., checking whether there are wavy edges, zinc ripple, zinc lines, whether there are bulges, indentations, folds, scratches and other appearance quality problems.

-

03

Finished product inspection

Finished product performance testing is the most important part of all the testing process, which will affect the inherent quality of the product in later processing and use. The following items are mainly tested: width, thickness, plate shape, plate quality, coating weight, coating bending and impact and other performance tests.

Among them, color coated products also need to be strictly tested for coating, testing items are: color difference, coating thickness, MEK, pencil hardness, impact, T-bending, coating aging resistance and salt spray test sampling, etc.

-

04

Packaging Inspection

After the product quality inspection is qualified, it is packed into the warehouse. Before warehousing, we need to check whether the packaging is standardized, whether the label printing meets the requirements, etc.

-

05

Sample Retention

Every product of the company will keep a sample to keep, so that customers can trace the cause of problems in the process of use, as well as subsequent continuous orders to maintain product consistency.

CN

CN AR

AR PT

PT RU

RU