Aluminum sheet coil

Description

Product Introduction

Aluminum is the most widely used non-ferrous structural materials in the industry, with its light, good electrical and thermal conductivity, high reflectivity and oxidation resistance characteristics, with the development of aviation, construction, automobile and other important industries, the demand is increasing, the application is very wide. Aluminum sheet according to the alloy composition can be divided into: 1. High purity aluminum sheet (content of 99.9 and above high purity aluminum rolled); 2. Pure aluminum sheet (the composition is basically rolled from pure aluminum); 3. Alloy aluminum sheet (composed of aluminum and auxiliary alloy, usually aluminum copper, aluminum manganese, aluminum silicon, aluminum magnesium, etc.); 4. Composite aluminum sheet or brazed plate (through a variety of material composite means to obtain special purpose aluminum sheet materials); 5Alclad aluminum sheet ( it is an aluminum alloy with a protective cladding of aluminum to improve its corrosion resistance).

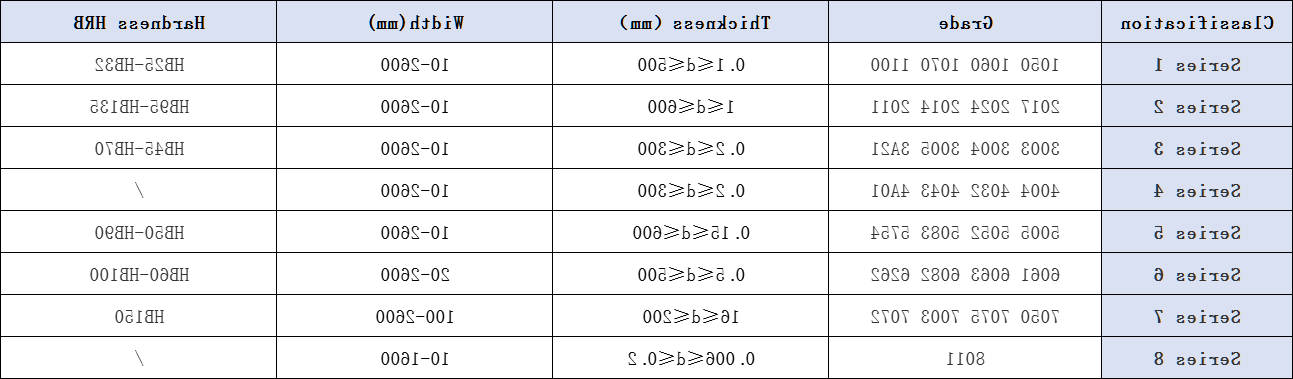

According to the alloy composition, aluminum sheet can be divided into 1-9 series:

Series 1 aluminum alloy represents 1050, 1060,1070,1100, etc., the hardness is between HB25-HB32, containing more than 99% aluminum, good conductivity, good corrosion resistance, good welding performance, low strength, can not be strengthened by heat treatment. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap.

Series 2 aluminum alloy represents 2017,2024,2014,2011, etc., and its hardness is between HB95-HB135. Series 2 aluminum alloy is characterized by high hardness, among which copper has the highest content, about 3%-5%. Manganese, magnesium, lead and bismuth are also added to improve the cutting property, which is widely used in aerospace, automotive and shipbuilding fields.

Series 3 aluminum alloy represents 3003, 3004, 3005, 3A21, etc., with hardness between HB45-HB70, it is a series with good rust prevention function. Manganese is the main component, and the content is between 1%-1.5%. Non-heat treatment strengthening, good corrosion resistance, good welding performance, good plasticity, but low strength, can be hardened by cold work to strengthen the strength.

Series 4 aluminum alloy represents 4004,4032,4043,4A01, etc. This series of aluminum alloy is silicon as the main alloy element, silicon content between 4.5% and 6%. Due to the high silicon content, low melting point, good melt fluidity, easy to fill, and will not make the final product brittle, so it is mainly used for manufacturing aluminum alloy welding additive materials, such as brazing plate, electrode and wire. In addition, some of these alloys are also used to make piston and heat-resistant parts because of their good wear resistance and high temperature properties. Alloy containing about 5% silicon, after anodic oxidation color black gray, so suitable for building materials and manufacturing decorative parts.

Series 5 alloy represents 5005, 5052, 5083, 5754, etc., with hardness between HB50-HB90. Its main characteristics are low density, high tensile strength, high elongation, and good fatigue strength. However, it can not be strengthened by heat treatment, but can only be improved by cold working. The main element is magnesium, and the magnesium content is between 3% and 5%. Also known as aluminum magnesium alloy.

6 series alloy represents 6061, 6063, 6082, 6262, etc., the hardness is between HB60-HB100, the series of aluminum alloy mainly contains magnesium and silicon two elements, so concentrated the advantages of 4 series and 5 series, medium strength, good corrosion resistance, good welding performance, good process performance (easy extrusion forming) oxidation and coloration performance.

7 series alloy represents 7050, 7075, 7003, 7072, etc., the hardness is generally around HB150, the series of aluminum alloy mainly zinc, but sometimes a small amount of magnesium, copper. It also belongs to the aviation series. It is a heat-treatable alloy and belongs to superdural alloy. The superdural alloy is containing zinc, lead, magnesium and copper alloy, has good wear resistance. It also has good weldability.

Series 8 alloys represent 8011 etc., belonging to other series. Commonly used as aluminum foil, such as beer foil, household foil, air conditioning foil, and a few cable foil.

Series 9 aluminum alloy for the spare alloy series, technology is now so developed, in order to cope with the appearance of aluminum plate containing other alloy elements, the international aluminum plate belt Federation indicated that 9 series aluminum alloy for the spare series, waiting for a new variety to appear to fill the gap of 9 series aluminum alloy.

Product Features

-

01

Easy to process. Casting aluminum alloy with good casting performance or deformation aluminum alloy with good plasticity can be obtained by adding certain alloying elements.

-

02

Good conduction and thermal conductivity. Aluminum is second only to silver, copper and gold in conducting electricity and heat.

-

03

Low density. The density of aluminum and aluminum alloy is close to 2.7g/, about 1/3 of iron or copper.

-

04

High strength. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the strength of the matrix can be strengthened. Some grades of aluminum alloy can also be strengthened by heat treatment.

-

05

Good corrosion resistance. The surface of aluminum is easy to naturally produce a layer of dense and firm AL2O3 protective film, which can well protect the matrix from corrosion.

Brand parameter information

CN

CN AR

AR PT

PT RU

RU